frequently

What format should I send my work in?

Most preferable are print-ready PDFs. Microsoft Word, Corel Draw and Publisher files can be tricky. Before sending your file to us, please save it as a PDF. This alleviates any confusion.

How do I get my artwork to Comprint?

If files are under 10MB in size, please send via email to the member of our team that you have been dealing with. Alternatively you can send your artwork to info@comprintgroup.com. If the file size is larger than 10MB, please send the file via WeTransfer – click on the upload icon in the footer of our website to do so.

What resolution should my images be?

The higher the resolution, the better the output will be. The following is a guide to resolution required:

- Large format – 150-300dpi

- Laser printing – 200-300dpi

- Litho printing – 300dpi

What is the difference between CMYK and RGB?

RGB refers to red, green and blue light that make up the screen display on our computer monitors. CMYK refers to ink colours in the printers (cyan, magenta, yellow and black). Printing is always done in CMYK colour and spot colours.

Please ensure your artwork is saved as CMYK colour, or spot colours as follows:

- CMYK – 4 process colour

- Spot – pantone colours

What is bleed?

Bleed is the area on a page that is to be trimmed. If you need a design to essentially ‘run off’ the page, you’ll need to apply bleed around your design to ensure you get the desired effect.

What is litho/offset printing?

Litho printing dates back to 1796! It was invented by German author and actor, Alois Senefelder, as a cheap method of publishing theatrical works. Today, the same sentiment exists. Litho is a very cost effective method of printing large volumes using custom plates for each page.

What is your smallest litho run?

Our minimum run for any litho job is 500 sheets, but chat to us. You might succeed in twisting our rubber arm! It all depends on your job specs and our production schedule.

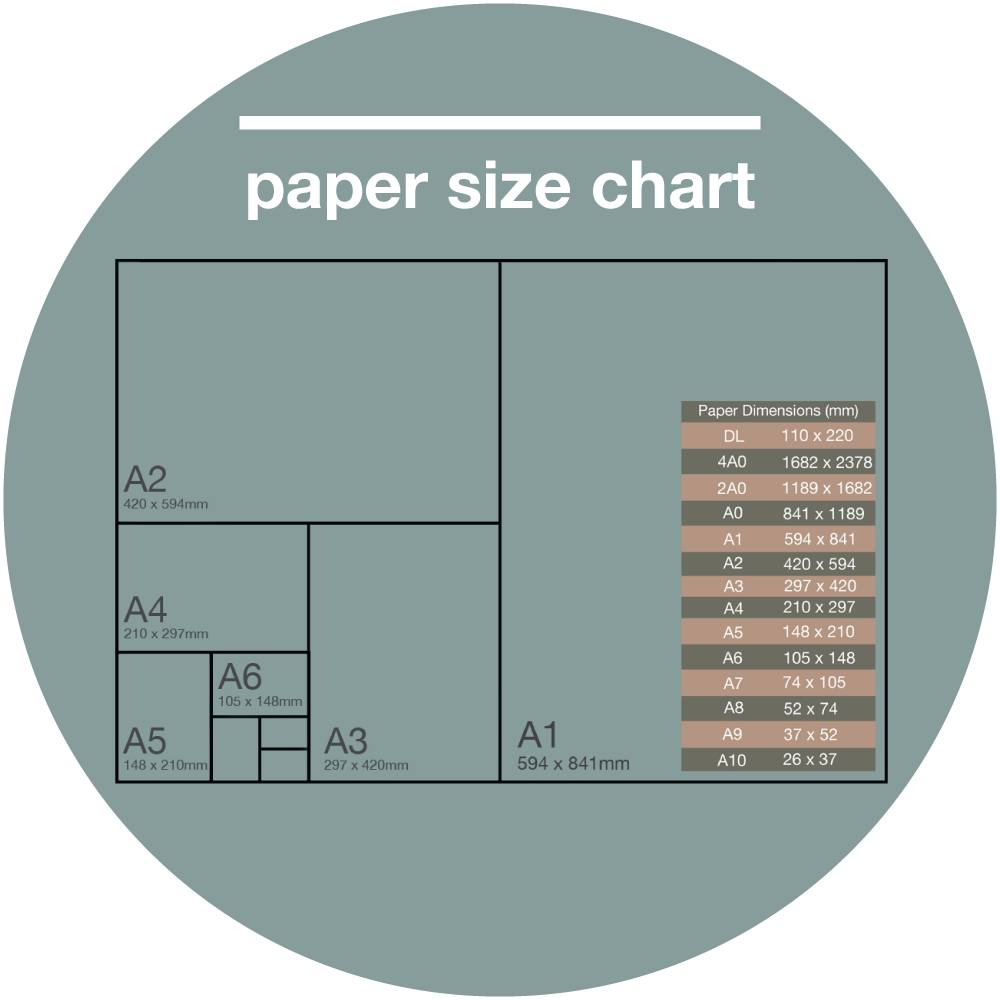

What is the biggest you can print?

On Litho the maximum print size is A1 (594 x 841mm); Digital maximum is 660 x 330mm. On our large format printer, we can print up to a width of 1 189 mm with unlimited length.

What is the heaviest media I can print on?

On litho, maximum weight is 450gm. On digital, 350gm is the maximum grammage we can print on. However, on our large-format machine, we can print up to 960gm.

What paper stock do you supply?

We carry the following print media at all times:

- Bond

- Pro Design

- Galerie Silk/Gloss

- Munken Pure/Polar/Lynx

- Conqueror Laid/Bamboo

- Haddonia Ivory Smooth/Linen

- Eurotak Adhesive Sheets

Large format media (on roll):

- Bond 80gm

- Bond 125gm

- Canvas 410gm

- Semi-Gloss 250gm

- Matt 180gm

- Premium Lustre 260gm (premium quality photo paper)

- Hahnemühle Photo Rag 305gm

For special printing, we can source any other media. Please chat to us.

Why do I need to see a printed proof before digital production?

What we see on our computer screens is often not at all what a printed equivalent might look like, so it’s imperative to sign off on the tangible proof. There are many different factors and components to printing that might change the final outcome from what it looks like on screen. We will often ask you to sign off on proofs electronically, if all that is required is proof reading, spelling, positioning, etc. However, before we go into production, we will ask you to come in and sign off on a proof/sample to make extra sure everything is perfect!

Can I see a proof before you go into litho production?

This is not possible as the machine has been set up for the particular job. Unfortunately we cannot halt production for an indeterminate time for a proof to be approved. A high-resolution Sherpa proof can be arranged, but at an additional cost.

Before we burn to plate, you will receive a proof of the positive to check for the following:

- All information present; details are correct (names, numbers, etc) and there are no typographical errors.

- All spelling is correct.

- The position of the copy is correct.

- The bleed is correct.

- Grip is correct.

- Imposition or stepping is correct.

- Trapping is correct.

- Size is correct.

Can I supply my own paper?

We prefer to print on our paper, which is supplied by reputable suppliers and vetted for our equipment. In exceptional circumstances we may consider printing on special paper supplied by you, but please pop in to discuss this before paper is acquired.

What is NCR?

NCR stands for Non-Carbon Reproducing paper. It refers to a 60gm paper used for carbon books such as invoice books, delivery note books, receipt books, etc. Typically, we print these books lithographically with duplicate or triplicate copies. We can print in any size, for example A4, A5, A6 or custom size.

What is die-cutting?

Die-cutting is the process of cutting specific shapes or forms out of ordinary sheets of paper so you can make custom products such as door hangers, key card wallets, licence disc stickers, etc. We make up a die, which is essentially a block of wood specifically designed in the shape of the end product. Much like a cookie cutter is used to cut shapes out of dough!

What is kiss-cutting?

While this sounds awfully romantic, it’s similar to the die-cutting process (see above). But instead of cutting straight through, it simply ‘kisses’ and does not pierce the label’s backing material. It’s ideal for stickers, which remain on the sheet and can be peeled off the backing material when required.

What is pur binding?

PUR binding is a type of adhesive binding where a thin layer of glue is spread across a book’s spine, with a paper cover folded over the top to create a finished product. If you’re interested in using this method to finish a book, take a look at our PUR Binding Check Sheet to make sure you provide us with everything we’d need to make your vision visible!

Do you offer variable data merging?

We sure do! Take a gander at our Variable Data Merge Check Sheet for easy-to-follow steps on how this process works and what we’d need from you to make it all happen.

How do I package a file in InDesign?

Who can help me with my design?

Our team can! We’d love to help you make your creative vision visible. Book an appointment below to chat through all your design needs.

connect

with us

We would love to help make your vision visible.

Give us a call or stop by our print work-room!

021 887 3883

info@comprintgroup.com

Chardonne Farm, Gate 2

Blaauwklippen Road, Stellenbosch

We’re Open:

Monday – Friday | 8:30 – 16:00

Except Wednesday | 9:00 – 16:00